Luggage Materials

Luggage Materials

Ballistic Nylon

Tumi - Meridian Carry-On WAW Duffel

When one thinks of ballistics, weaponry is most likely the first thing to come to mind. Bullets, rockets, and miscellaneous projectiles all qualify under the ballistic category. So what do weapons have to do with luggage? The tarmac is probably the closest your luggage will get to a war zone, so many luggage makers have turned to a ballistic nylon fabric to ensure that your possessions will survive the trauma of being checked in. Ballistic nylon was originally used in the flak jackets of World War II airmen to protect against debris and fragmentation caused by bullet and artillery shell impacts. In the mid 1980s, Tumi was the first company to achieve the landmark of incorporating ballistic nylon into luggage. Other brands like Victorinox, Hartmann, and Briggs and Riley followed suit shortly thereafter. Since its debut in the travel industry, this tough-as-nails material has proven to be one of the most trusted and durable fabrics seen surviving the airports.

When considering baggage materials, ballistic nylon fits the bill for the constant traveler. If your bag is made from ballistic nylon, you are choosing a material that can take a beating. Ballistic nylon’s “filament” yarn makes it a step smoother and stronger than common nylons, like cordura, which is less compact and rougher than the weave of ballistic nylon. The other major identifier of a ballistic nylon is a two-ply weave, adding that extra stability needed to handle rough conditions.This durability and a fine texture have made ballistic nylon a popular choice for business travelers in need of a classic baggage look in a fabric that will stand up to the tumult of checked luggage travel.

Dating back to the 13th century, canvas is one of the most tenured materials in the bunch. Although historically made from hemp, from whence it derived its name, modern canvases are made of either cotton or linen. Canvas also has two basic types: plain and duck. The only difference between these two designations is that duck canvas is threaded more tightly than plain canvas, adding to its durability. There are also various subtypes of canvas: waxed, waterproof, water-resistant, stripe, printed, fireproof, and dyed. In the United States, canvas is classified by both weight (ounces per square yard) and grade. In this graded number system, the numbers count down, so a number 10 canvas would be lighter than a number 5. Canvas is used for many things: painting, sails, tents, signs, backpacks, and luggage, of course. One of the more well-known brands using canvas is Filson, made in Seattle. There is a reason canvas has been used in luggage for such a long time, and that is because it has been proven to be a strong, durable fabric. Although not the lightest fabric around, canvas will be sure to protect your belongings.

Choosing canvas luggage material is committing to a look that embodies a return to a natural, organic, and traditional fabrication. It also is an evolving fabric in the luggage industry that has taken backpacks, messenger bags, and duffels by storm. This material has been a significant fabric that has aided in the transition between the casual nature of the modern business person, while also representing an easy travel look. If you want a luggage that is protective, rugged, and packed with character, canvas will be your luggage material choice.

The practice of utilizing animal hides has been around since the dawn of man. These early rawhides had a tendency to dry out quickly, thus rendering them useless. In modern times leather has taken rawhide a step further via the tanning process that fortifies the material and prevents it from drying and cracking. Over the years several methods of tanning have been created. Various animals' hides have been included into the leather making process, and as a result many types of leather have been made possible. Leather is generally sold in four forms, although other forms exist: full-grain, which has not been buffed to remove imperfections, top grain, in which only the surface is buffed, corrected-grain, in which an artificial grain is applied to the surface, and split, where the leather is created from the fibrous part of the hide left over from the removal of the top grain. Two other common leathers that you will see among our brands are belting leather, and napa leather, which can be found in collections from Tumi, Hartmann, and Filson. Obviously, leather has stuck around so long not only because it lasts, but also because the processes developed for its production give it both beauty and class.

When you choose to invest in a leather bag, you are recognizing that you want your bag to live and evolve with each trip alongside you. Leather will take in character as it ages and each piece becomes unique to your experience with it. Someone who invests in a leather bag invests in making an impression. As one of the most sought after materials on the market, leather continues to be a favorite for all types of travelers. Business travelers, frequent flyers, casual vacationers, and many more continue to find leather to be a statement luggage material that is sure to stand out for its look and high quality.

Nylon has been used in luggage for quite some time. Initially developed by the DuPont Corporation in 1935, nylon took a few years to be commercialized before taking off as one of the most successful materials to date. First used in toothbrushes, nylon can now be found in clothing, machinery, musical strings, pipe, rope, carpet, and luggage to name only a few. Chances are that you have owned or know someone who has owned a piece of nylon luggage. After the old steamer trunks were rendered obsolete and aluminum luggage wore out its stay, this wonder material was pretty much all there was in the luggage industry until polycarbonate came along. One of the great things about nylon is that it is such a strong, adaptable material. Nylon can be used as a matrix material in composite materials with reinforcing components such as carbon fiber or glass, which increase its durability exponentially. When mixed with such materials, nylon can rival the durability of most metals.

Nylon is the no-fuss material for the traveler who likes a bag with easy upkeep. Not only does it have the benefit of being able to be washed- a large bonus compared to other fabrics that can tend to show dirt, dust, and wear, but need professional grade cleaning- this bag material is also incredibly lightweight. Nylon also tends to be the fabric that brands will give the most color variance in. Brands like Lipault, Tumi, and Swiss Army all feature fantastic collections that venture into colorful nylon fabrications. Nylon won’t fray like other luggage materials, and its synthetic fibers have the added bonus of repelling water rather than canvas and other threads that take in water and tend to soak more easily. If you are looking for a versatile look that remains durable, nylon is the fabric for you.

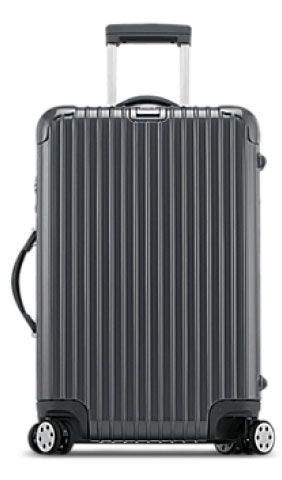

Polycarbonate refers simply to a group of thermoplastic polymers containing carbonate groups. In short, a synthetic material that can be easily molded. Polycarbonate has a high impact resistance and is incredibly lightweight: two very important factors when considering new luggage. In 1955, NASA started using polycarbonate for its helmets and visors, which were the first type to take that giant leap for mankind. It wasn't until the year 2000 that the German luggage maker Rimowa started making their suitcases from polycarbonate. Today, virtually every luggage brand has a line made from the material. There are many grades and types of polycarbonate, but luggage is only made from a few of them. Rimowa Luggage, Antler, and Victorinox Luggage are crafted from grade A 100% virgin polycarbonate, which basically means it's in the purest form at the best quality. Other brands are made from grade B or C recycled polycarbonate. This means that an already existing piece of polycarbonate has been reduced to pellets, ground, and re-molded into another polycarbonate product. Rest assured, even though a polycarbonate case has been made from recycled materials, the nature of polycarbonate is such that its properties don't deteriorate significantly after being re-purposed if proper methods are taken. A quality polycarbonate case can be pretty pricey, but for a very good reason: it's one of the strongest materials luggage is made from. Some common items made of polycarbonate include bulletproof glass, compact discs, safety goggles, and helmets. If that doesn't indicate how strong polycarbonate actually is, we don't know what else would! In addition to being incredibly impact-resistant, polycarbonate is exceptionally light. Some carry-on pieces only weigh 4 pounds; that's less than a newborn baby. There are even 32-inch cases that weigh in at around eight or nine pounds: still less than some newborns.

For those who require that their luggage be lightweight, scratch resistant, and can stand up to the rigours of travel, polycarbonate is the material you will want. Polycarbonate will not only help guard your possessions from the rigors of the cargo hold, but also prevent having to fork over an exorbitant amount of money for being over that awful 50 pound weight limit!

PVC

For some, leather is not an option due to religious and/or personal reasons. For others that travel often, leather simply does not hold up as well as synthetic materials. PVC is science's answer to a more resistant leather alternative. It was accidentally discovered at least twice in the 19th century by Henri Victor Regnault in 1835 and Eugen Baumann in 1872. Today, PVC is the third most widely produced plastic behind polyethene and polypropylene. PVC is mainly used as a construction material, as it is strong and more efficient than traditional building materials like wood and metal. PVC has become more commonly used in the making of luggage, because it is waterproof and much cheaper to manufacture than leather. At the same time it has an incredibly beautiful feel and look to it that has the feel and look similar to suede. The brand that stands out in the Kaehler collection for its PVC use is Bric's, who use a blend of cotton and PVC to craft some of their beautiful luggage.

If you’re thinking about buying a PVC luggage it is because you are looking for a stronger alternative to leather that will withstand scratching when you check luggage. A PVC style is also for the luggage owner who is looking for a unique fabric that has a more luxe and soft feel than the normal nylon design and proves to be a durable alternative to leather.

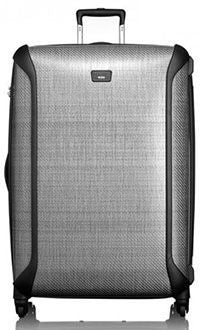

Tegris is one extraordinary material. Developed by Milliken & Company, and making its debut with Tumi Luggage in 2012, Tegris is the wunderkind of composite materials. Tegris starts out with a series of tape-like strands of polypropylene. Polypropylene, similar in its make-up to polycarbonate, is another material with incredible strength. The strands of polypropylene are then woven into a fabric-like sheet. This sheet is then heated, pressed, and stretched to form one piece, which can then be molded. Depending on the product, there could potentially be many more layers pressed together. The outer layers are melted together to form a type of resin coat, which gives the product a nice finish. Institutions using Tegris include NASCAR, which uses over 100 layers of Tegris in its Aero Splitter bumpers, the US Armed Forces, which employ Tegris to protect the troops in Humvees, and Riddell in football shoulder pads. Tumi also hopped on the Tegris trend, crafting a new line of luggage: Tegra-Lite. Its success exceeded anticipation and the line sold out everywhere within its first month and a half of being in stores. This indestructible luggage is definitely something to check out!

Tegris is the luggage material choice for the traveler who is looking for a different style of the hard-case exterior. The woven fabrication is lighter and more flexible, which means that you, as a traveler, benefit by getting to pack it even fuller on the inside. Tegris’ flexibility will be able to take more pressure, and actually performs better when it is being packed to the brim as its exterior becomes that much more reinforced. On top this, Tegris fabric can be dyed to some extravagant and rich colors that are truly beautiful to behold. Altogether, Tegris is for the Tumi user looking to branch into a new direction with their collection.